- Continue to search products

- Go to inquiry

Sealing End Cover also known as Blind Cover, Cover Seal, Sealing Cap.

The Sealing End Cover is used to close bores or to replace bearing seals.

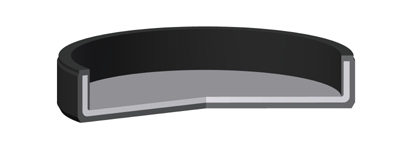

The Sealing End Cover – NBEC NBR-70 (black) is a standard End Cover Seal that consists of a rubber-coated metal part. The Sealing End Cover is designed to seal against grease, oils and water in rotary applications. A standard Sealing End Cover is designed to run at a maximum pressure of 0.5 bar.

PROFILE

PRODUCT ADVANTAGES

• Can be used both for static and rotating applications

• Good resistance to many mineral oils and greases

• Medium ageing resistance

• Wide range of dimensions

• Easy installation and removal.

• Economical sealing solutions

APPLICATION

Used in almost every industry as a good reliable sealing in rotating machines, shafts, axles, power tools and gearboxes. End Covers are used to secure sealing in openings for shafts or axles and to plug seal service bores.

INSTALLATION

Installation according to DIN 3760. It is very important that the assembly tools must be of soft material and have no sharp edges. For installation use a hydraulic or mechanical pressure device to press the sealing end cap into the housing bore hole or gently use a rubber hammer to carefully hit the sealing end cap into place. It is important to distribute the pressure or hammer strikes evenly over the whole surface of the end cap.

NOTES

For special applications that require high temperatures or pressure, other materials and models can be used. Please see our other end covers in FPM. For higher pressure use a circlip to secure the end cover seal.