- Continue to search products

- Go to inquiry

NBR (Hydrogenated Nitrile Butadiene Rubber) is made via selective hydrogenation of the NBR and improves the thermal and oxidation resistance of the material.

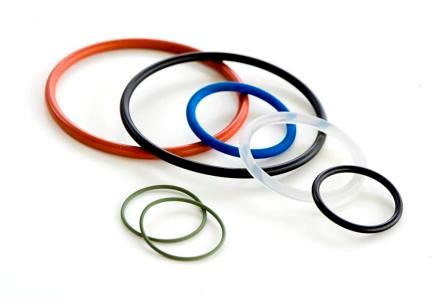

O-rings are the most common sealing element, and because they are cheap and simple, the area for application of O-rings is very wide in hydraulic and pneumatic systems. Where working conditions and equipment are suitable, they can be used both in static and dynamic applications, but they are not recommended for rotary movements.

Because they take up less space and provide two-sided sealing compared with other sealing elements, O-rings make designing easier. Obtaining good results from O-ring applications depends on suitable measurements, choosing correct materials, and suitable surface quality on metal parts.

PROFILE

PRODUCT ADVANTAGES

• Can be used both for hydraulic and pneumatic systems

• Can be used both for static and dynamic applications

• Both for rod and piston applications

• Wide compound range

• Wide range of dimensions

• Easy installation and removal

• Good resistance to mineral oils and mechanical wear

• Improved resistance to heat, ozone, ageing and weathering compared to NBR

APPLICATION

Used in almost in every industry but especially in non-moving machinery and in static sealing applications, e.g. as flange or cover seals.

HNBR O-rings have good resistance to mineral oils and mechanical wear and an improved resistance to heat, ozone, ageing and weathering. HNBR also has good resistance to some refrigerants.

INSTALLATION

O-rings are fitted into the groove by hand. It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation all individual parts of the seal must be oiled with system oil.

Tolerances: DIN 3771 / ISO 3601.